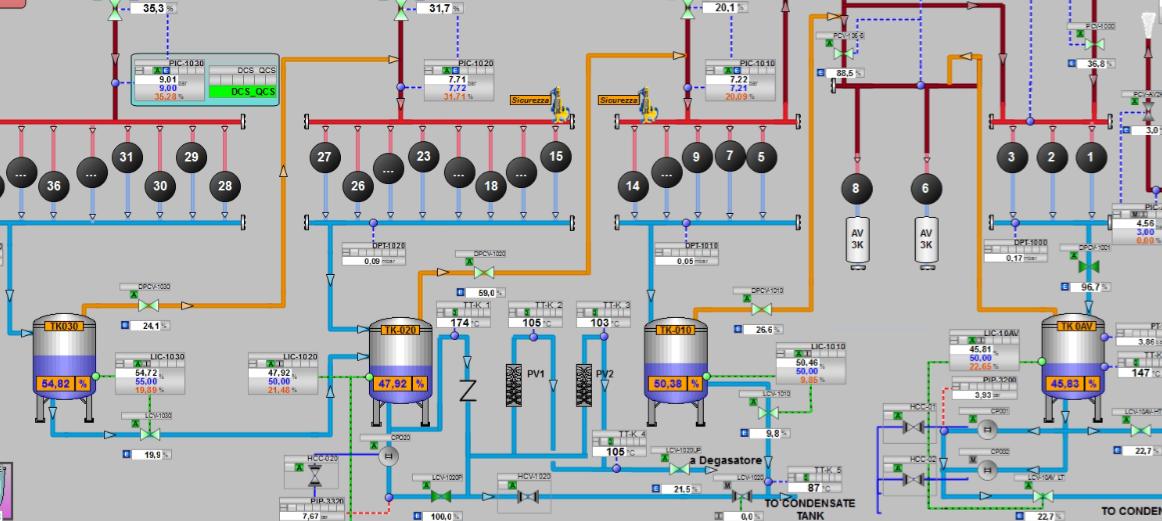

Control

Equipment and process automation

“We push automation beyond the industry standard’s limits, both for flow calculations and energy balance, increasing production thanks to our system’s self-diagnosis that reduce consumption and increase production, always maintaining the highest thermal efficiency possible”.

Pressure controls with blow through managing, Master-Slave strategy according to the Mollier curve, warm up procedure, management and control of energy surges, ecc. Are only some of our trademark control strategies of automation by SAM Progetti.

- New automation and control standard with DCS and QCS

- Machine start up, warm up and cool down in complete automation

- Change of production in complete automation

- Competence system for the management of paper machines

- Automatic self-diagnosis for DCS and QCS

- Automatic automation of thermodynamic Energy transfer

“Automation applied to an inefficient operation will magnify the inefficiency”

Safety and Redundancy

SAM Progetti’s original and proprietary process control technology integrates custom-built hardware with software tailored to each specific machine, enabling operations and performance (guaranteed by contract) that are unexpected and unattainable by TAPPI technology currently used by all our competitors.

Our control software is designed to minimize operator effort and reduce the possibility of errors, while enhancing their capabilities and expertise without the need for experienced paper mill personnel: a system that is simple to operate but delivers extraordinary performance.